Risk assessment

Determine the risks posed by defects

Use CausewayOne Asset Management to adopt a risk-based approach to asset management and maintenance.

By assessing the level of risk posed by a defect, it can help to determine whether an asset requires reactive maintenance, or can continue operating until its next planned maintenance.

For example, if a deep pothole poses a high risk to drivers, it requires an emergency repair to make it safe. Conversely, it may be safe for a low-risk pothole to remain until the road is next resurfaced.

A common method of calculating risk involves two parameters:

- Risk likelihood

- Risk consequences

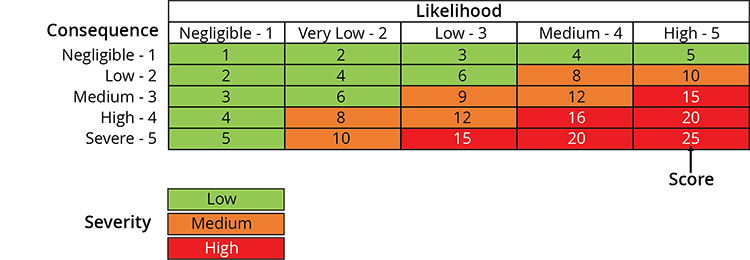

By assigning each parameter a set of possible values, and then mapping them against each other, you can calculate the severity of the risk. The following table illustrates a basic risk assessment scenario, where multiplying the likelihood score by the consequence score produces an overall risk score.

While the possible values of the risk likelihood and the risk consequence can vary, the general principle is common to most methods of calculating risk.

Risk Assessment module

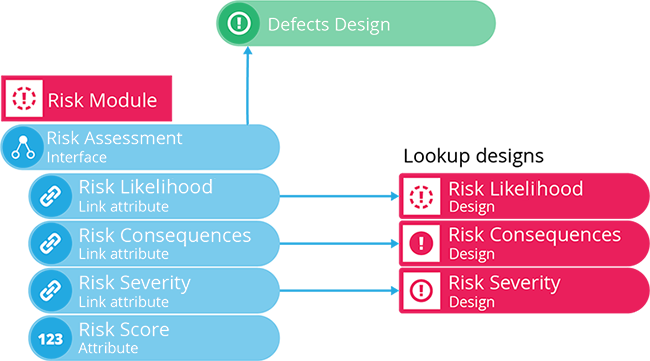

To get started with risk assessment, the corresponding module must be installed for your organisation. The module consists of a risk interface, three risk designs and a risk calculation workflow.

Risk interface

The risk interface contains four attributes. The first three are Link attributes, which each store an item of the corresponding risk design. The fourth attribute stores the calculated risk score.

To add risk assessment to one of your defect designs, configure it to implement the Risk Assessment interface.

Risk designs

There are three risk designs. Create items of the Risk Likelihood and Risk Consequences designs to represent the possible values of each one, e.g. Rare: 1, Moderate: 4.

The Risk Severity design represents the severity of the calculated risk score. Create items of the design to represent each level of severity and its risk score range, e.g. Cat 2 (High): 10.5 to 16.5.

To learn more, see Using risk designs.

Risk calculation workflow

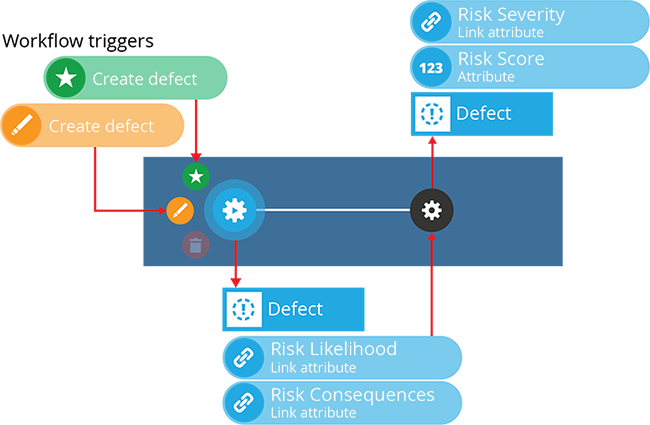

The risk calculation workflow triggers automatically when a defect (that implements the risk interface) is created or edited.

The workflow reads the defect's Risk Likelihood and Risk Consequences attributes and passes them to a mesh. The mesh responds with the calculated Risk Score, which then determines the defect's Risk Severity.

You can create a workflow that triggers when the defect's Status changes, which performs different actions based on the defect's Risk Severity.