Creating inspections

Examine and record asset condition data

Create inspections to check on the condition of assets, investigate possible defects, or verify completed jobs.

You can create a single inspection against one asset or a batch of inspections against multiple assets. You can add one-off inspections where needed, or set up a recurring schedule.

Alloy Mobile users can create and complete inspections while in the field.

Before starting, ensure that a design exists which defines the type of inspection you're about to create. Use the inspection designs provided with installed modules or create your own.

Start the process

There are several ways to start creating an inspection:

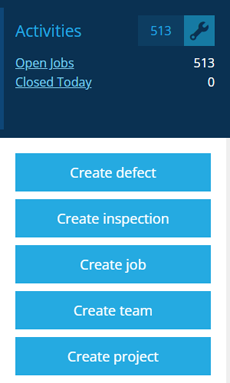

Start from the dashboard

Open the Activities dashboard card and select Create inspection.

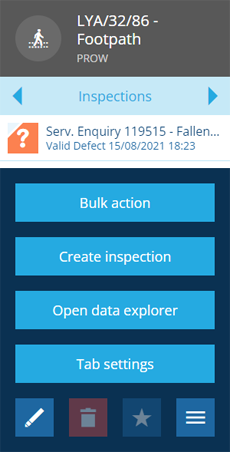

Start from an asset or activity item

To create an inspection for the item you're viewing, switch to the Inspections tab, select More in the action bar and choose Create inspection. The creation process will start with steps 1 and 2 configured automatically.

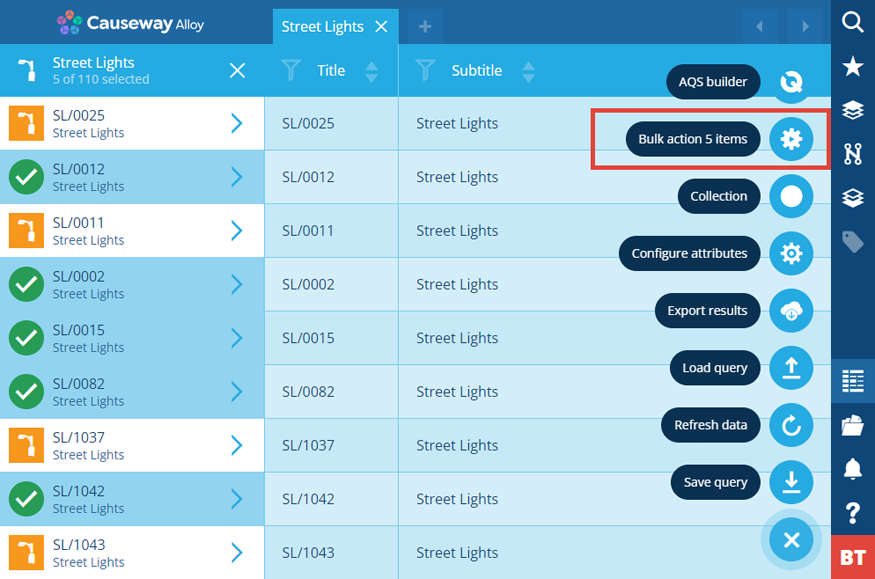

Perform a bulk action

When using Search or the Data Explorer to find asset or activity items, you can perform a Create inspection action on some or all of the item results. The creation process will start with steps 1 and 2 configured automatically.

To learn more, see Bulk actions.

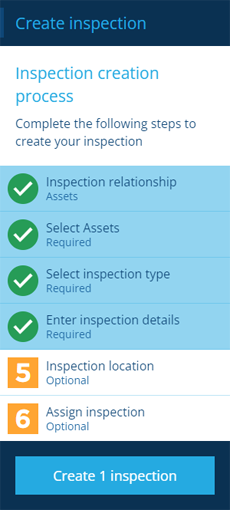

The inspection creation process

The key steps of this process will appear in the dashboard panel:

-

1 Inspection relationship - required

-

2 Select parent item(s) - required, unless the relationship is None

-

3 Select inspection type - required

-

4 Enter inspection details - required

-

5 Inspection location - optional

-

6 Assign inspection - optional

You don't necessarily have to enter all of the inspection's details upfront! Fields marked with an asterisk * are required. Other fields can be edited later.

1 Inspection relationship

Choose the type of item you want to create a new inspection for. This is usually set automatically, according to how you started the process. However, you can change it as needed:

-

Assets - inspect the condition of one or more assets.

-

Jobs - inspect the work output of a job.

-

Inspections - follow up a prior inspection.

-

Defects - investigate a reported defect.

-

None - perform an isolated inspection.

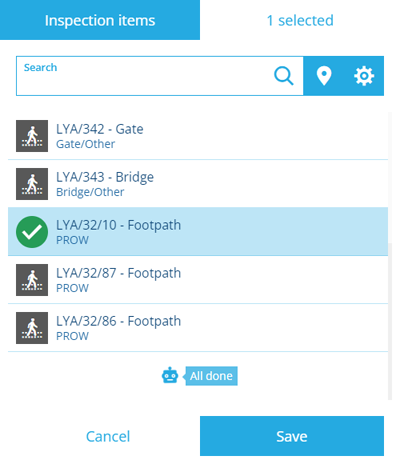

2 Select parent item(s)

Select one or more Inspection items of the type chosen in step 1. A new inspection will be created for each one. To select items visually based on their location, select in the item picker's search box to switch to the map picker.

Select Done to choose the next step.

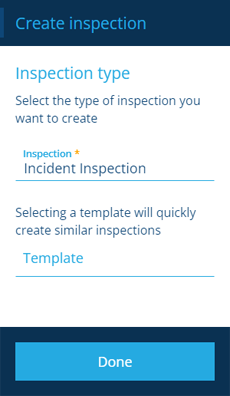

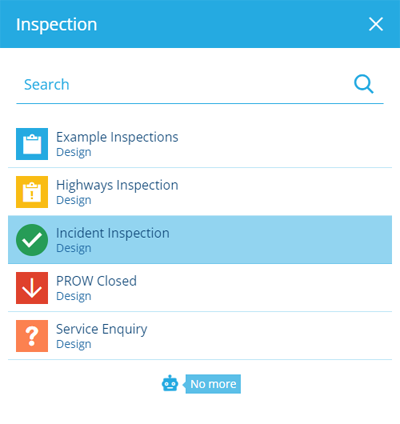

3 Select inspection type

Choose the type of inspection to create:

-

Inspection * - choose from a list of inspection designs that apply to the item(s) selected in step 2.

-

Template - pre-populate the new inspection(s) with values from an existing template item.

Select Done to choose the next step.

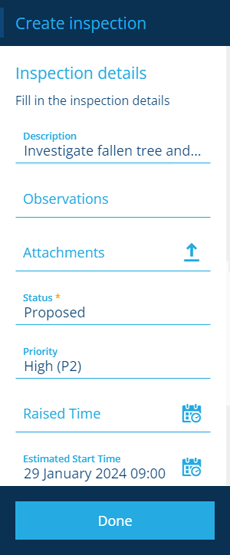

4 Enter inspection details

Enter values for the attributes of the inspection design chosen in step 3. Any required attributes * must contain a value to continue. Some attributes may be populated with a default value, such as:

-

Status * - is set to Proposed by default but can be changed.

-

Raised Time - if left blank, it will be set to the current date and time.

-

Inspection Number - an automatically generated unique number (not shown in this step).

Statuses and times

If you set Status to one of the following, the corresponding Time attribute will also be set to the current date and time (if left blank):

- In Progress ➞ Start Time

- Completed ➞ Completion Time

- Cancelled ➞ Cancelled Time

Select Done to choose the next step.

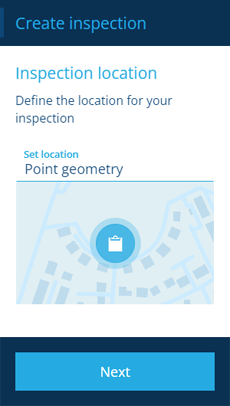

5 Inspection location

Depending on the inspection design chosen in step 3, this step may show as:

-

Optional - if left blank, the new inspection(s) will inherit the geometry of the parent item(s) selected in step 2 (providing the parent's geometry type is allowed on the inspection design). Alternatively, you can set a new geometry value! This is handy for situations where the shape/location of a inspection should be represented differently, e.g. to examine a pothole on a carriageway.

-

Required - you must set the new inspection's geometry. It won't be inherited from the parent item(s). This happens if the Requires geometry property is enabled on the inspection design.

-

No Geometry - the inspection can't store any geometry. This happens if the Allowed geometry property is active but empty on the inspection design.

-

Set from template - the new inspection's geometry will match the template item chosen in step 3.

To explicitly set the geometry of the new inspection(s), select this step and then Set location. Use the Geometry Editor to define the geometry and then select Save. By default, you can draw any geometry type, though this may be limited by the inspection design.

Select Next to choose the next step.

To specify which geometry types are allowed on a design, see Editing general design details.

6 Assign inspection

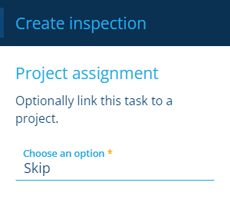

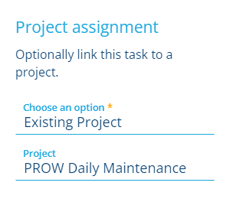

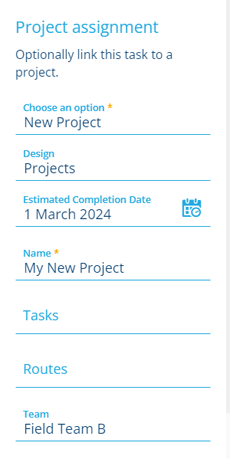

You can optionally assign the new inspection(s) to a project. By default, this is set to Skip.

Assign to an existing project

Assign to a new project

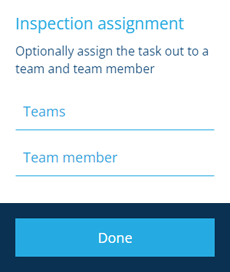

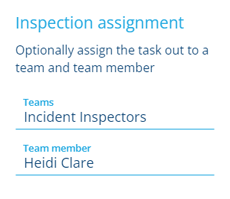

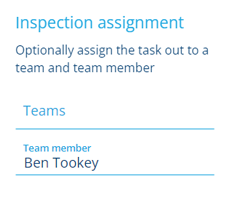

Also, you can optionally assign the new inspection(s) to a team.

Select Done to choose the next step.

Assign to a team

Assign directly to any team member

Finish the process

After completing the relevant steps, select Create to finish.

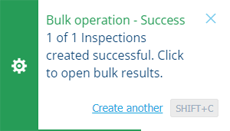

A notification will indicate whether the item was created successfully or an error occurred.

Create more inspections

To quickly create more inspections, select Create another in the notification before it disappears. The inspection creation process will restart with the previous values intact, which you can then change as appropriate for subsequent new inspections.

For more complex scenarios, you can build workflows that perform Create Item actions according to various conditions, which can be triggered automatically or on demand.