Standard inspection details

Attributes common to all inspections

All inspections have a standard set of details. They're defined as system attributes in the Inspections interface, which is implemented by all inspection designs. Therefore, all inspection items inherit the following attributes as standard.

Required attributes

These attributes are required on all inspection designs. A value must be set when creating/editing any inspection item:

-

Inspection Number - a unique ID number. This is automatically incremented, so the field isn't shown when creating/editing an inspection. By default, it's displayed in the title of inspection items for easy identification.

NoteYou can configure any Number attribute to automatically increment in this way.

-

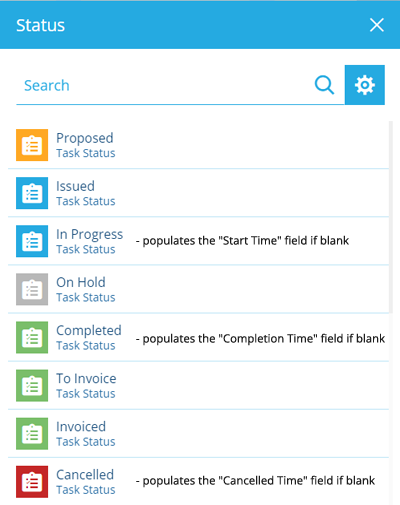

Status - indicates the stage that the inspection is currently at. Choose from a list of task statuses. Some will automatically populate a corresponding DateTime attribute if it's blank (see below).

Optional attributes

These attributes are optional on all inspection designs. They can be left blank when creating/editing an inspection item. While you can't make these system attributes required, you can use item forms to make their input fields require a value.

-

Attachments - any uploaded files associated with the inspection.

-

Description - text that typically describes any details of the inspection not covered by its other attributes.

-

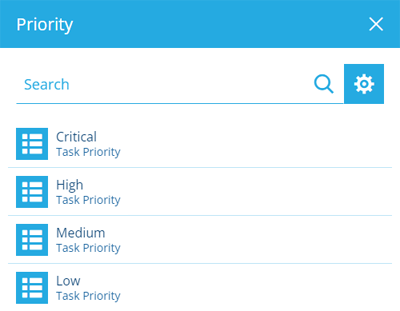

Priority - how urgently the inspection needs to be completed. Choose from a list of defined task priorities.

-

Team - the team the inspection is assigned to.

-

Team Member - the team member the inspection is assigned to.

-

Issued Time - when the inspection was assigned to a team or team member.

-

Estimated Start/End Time - when the inspection is expected to be started or ended.

-

Target Time - when the inspection is planned to be completed.

-

Raised Defects - any defects discovered during the inspection, which have it as their parent (see step 2 of defect creation).

-

Related Inspections - any other inspections that have this one as their parent (see step 2 of inspection creation).

-

Raised Jobs - any jobs arising from the inspection, which have it as their parent (see step 2 of job creation).

Automatic population

These attributes are optional on all inspection designs. If left blank, they'll be populated automatically when the Status attribute changes on an inspection item:

-

Raised Time - when the inspection was created (regardless of its initial status).

-

Start Time - when work on the inspection began and its status was changed to In Progress.

-

Completion Time - when work on the inspection finished and its status was changed to Completed.

-

Cancelled Time - when the inspection was cancelled, if its status was changed to Cancelled.

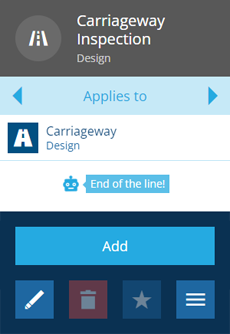

Applies To

To be usable, an inspection design must be set as applicable to one or more designs. This makes it selectable when creating an inspection for items of those designs. If an inspection design is applied to an interface, it will apply to all designs that implement the interface.

To apply an inspection design:

-

Select the design to view its details.

-

Use the tab bar to switch to the Applies to tab.

-

Select More in the action bar and choose Add.

-

Select one or more designs/interfaces and then select Save to finish.